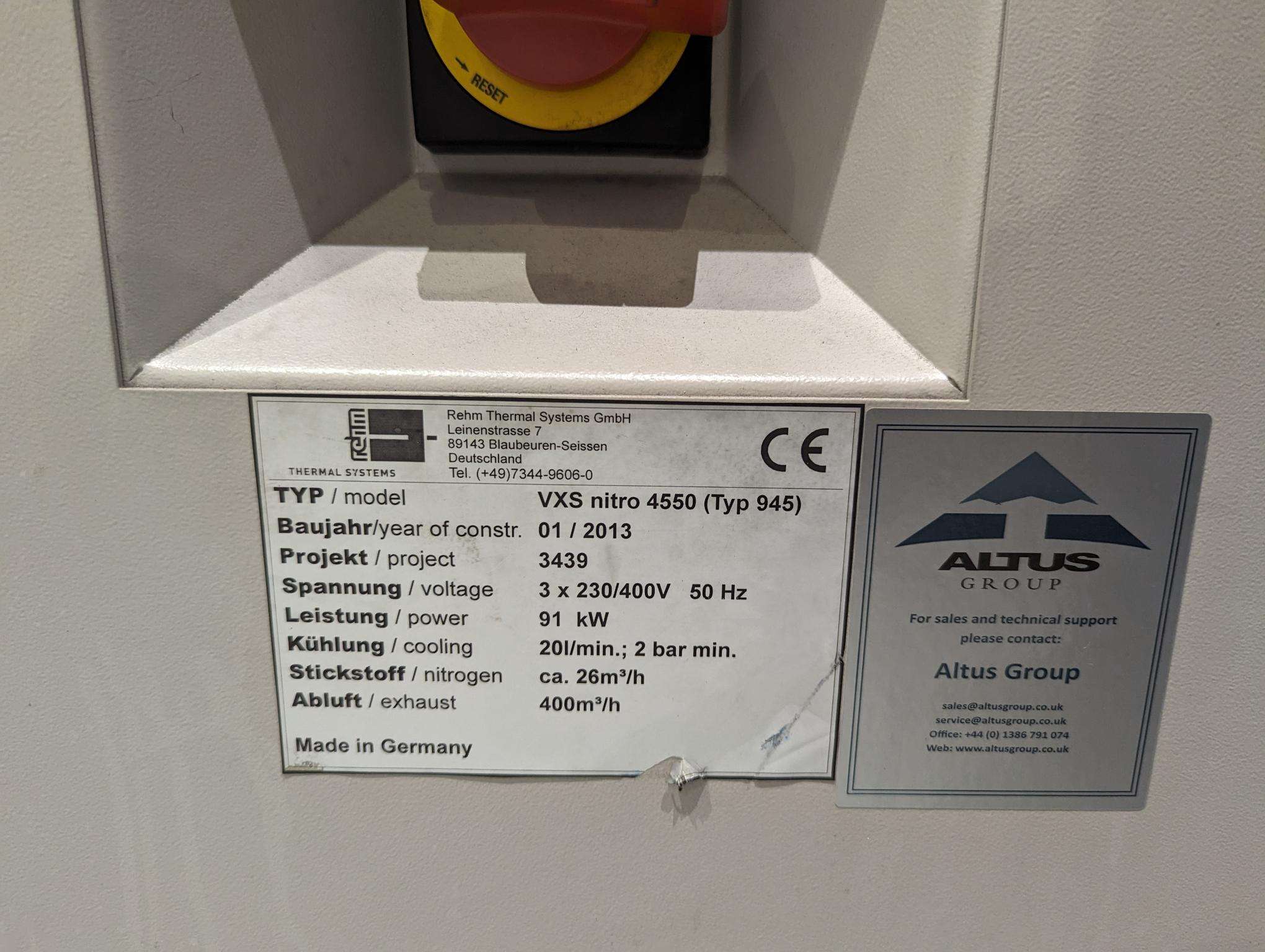

REHM VXS Nitro 4550 (Type 945) Oven

- Description

Description

REHM VXS Nitro 4550 (Type 945) Oven

Serial Nr.: 3439

Year of Manufacture: 2013

Direction: Left to Right

Transfer height: 900mm (+/- 75mm)

Process Chamber Heating:

- Length: 4550mm

- Qty of preheating zones: 9

- Length of preheating zone: 3150mm

- Qty of peak zone: 4

- Length of peak zone: 1400mm

Cooling Zone:

- Length: 1750mm

- Qty of cooling zone: 5

Cooling Water Flow: between 10-20l/min (according to temperature)

Operating Pressure: min 2 bar – max 5 bar

Nitrogen Supply Pressure: min 7 bar – max 10 bar

Voltage: 400 VAC, 3 Phase, 50Hz

Dimension (in mm): 7790 (L) x 1466 (W) x 1439 (H)

Weight: 5100Kg

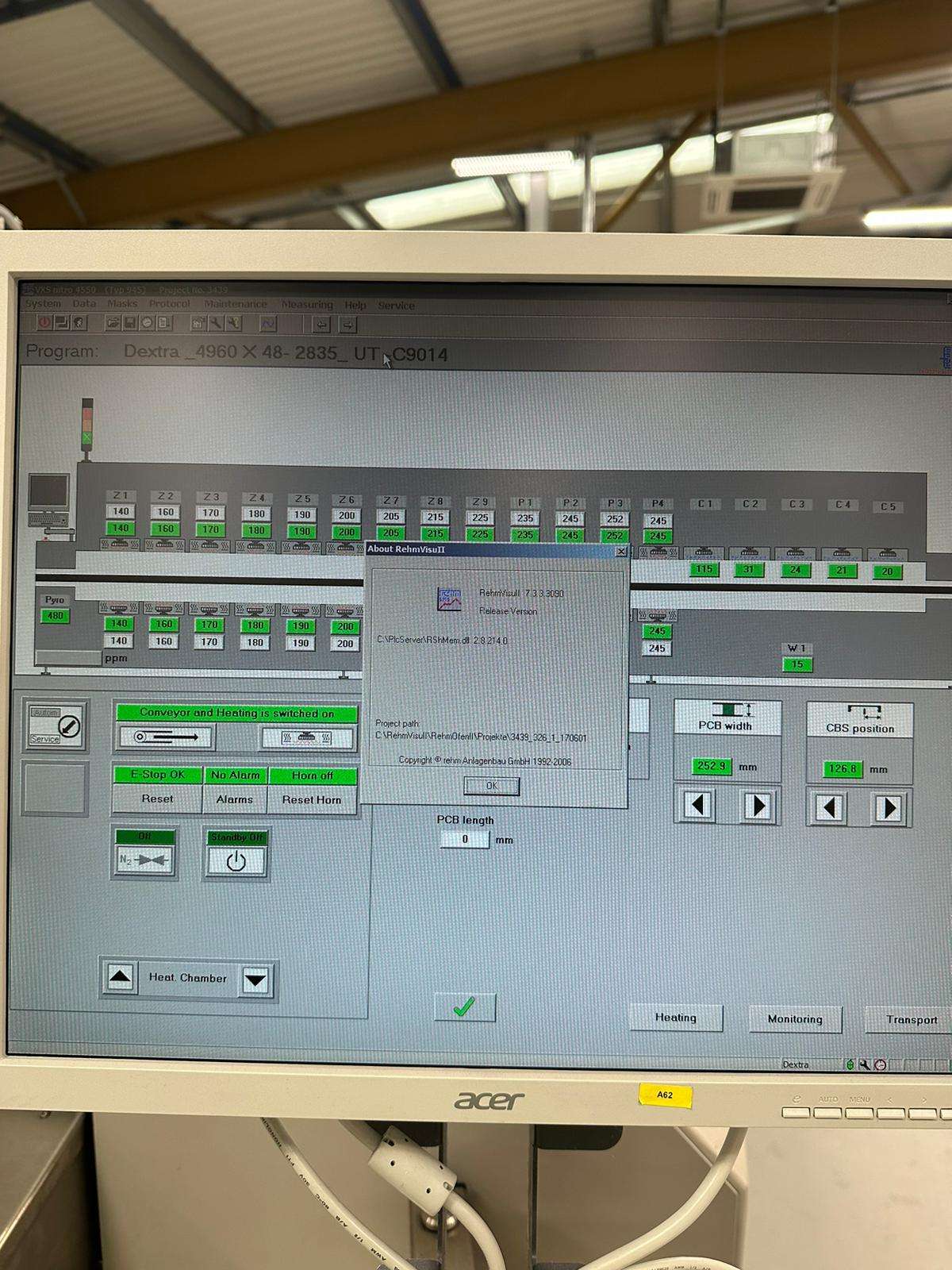

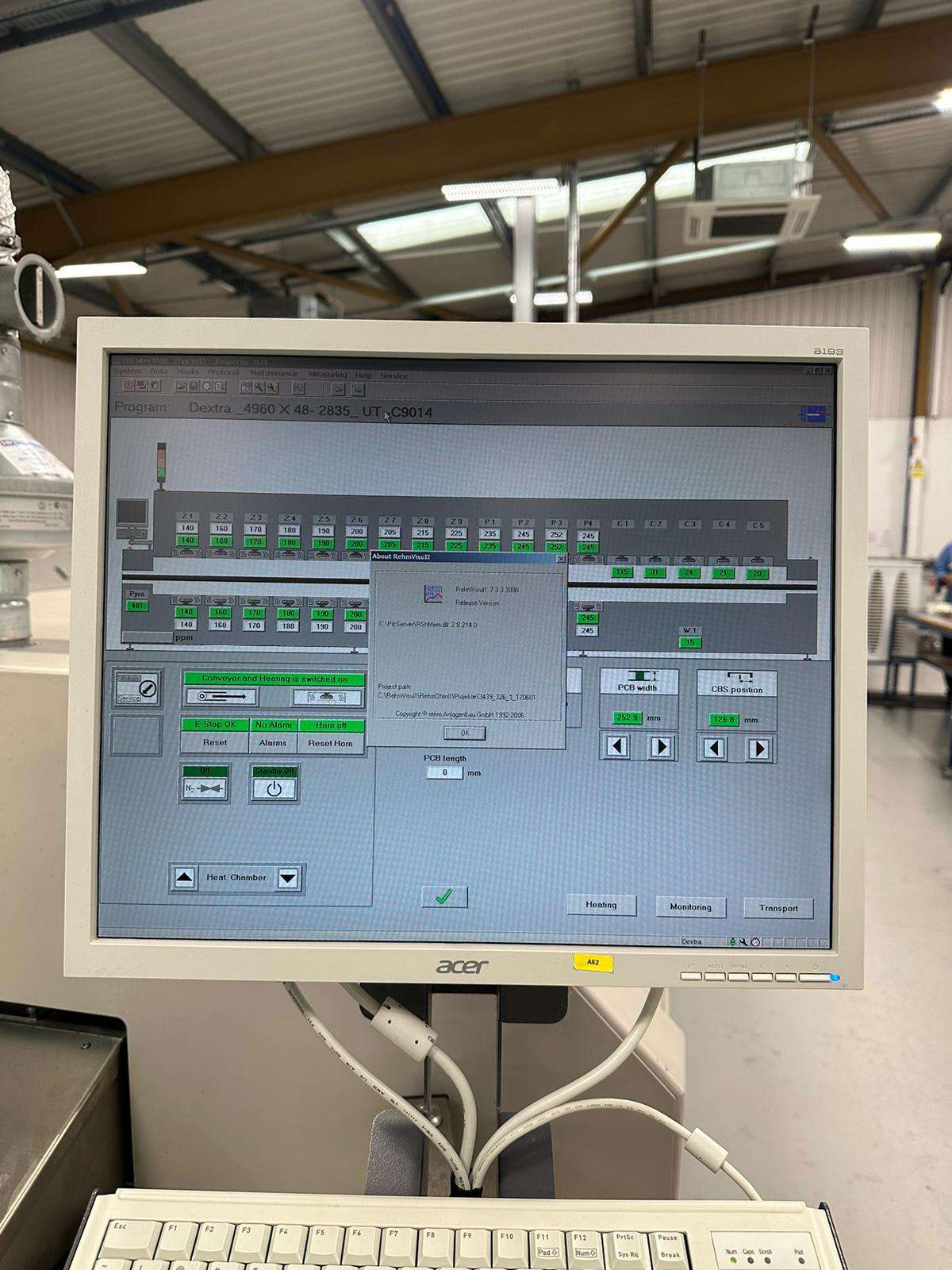

The system is a fully automated, convection-only Reflow soldering system which can be operated with air or nitrogen atmosphere. The PCB’s are advanced through various heat zones which are set to different temperatures for preheating, soldering and cool-down. The system is Equipped with a graphic user interface and can be operated with the included keyboard and trackball, or optionally with a touch screen.